DESCRIPTION

The exit is also equipped with a WASTE EJECTION and OPENING DEVICE. Quick changeovers are facilitated by fixed references. When die-cutting, nicks between the cut product and the waste are not required, thereby making the execution of the job easier and more precise, consequently improving in quality. Operation is by touch-screen panel with pictogram control. By using the interchangeable steel die plate and always keeping the same centred references, the execution of repeated jobs is simplified. Ideal for processing light and heavy paperboard.

Height of pile at the in-feeding: 1000 mm. Including pallet height.

Process possibilities: cutting, creasing, embossing, blind embossing (Braille), Kiss-cut applications including stickers.

ADVANTAGES

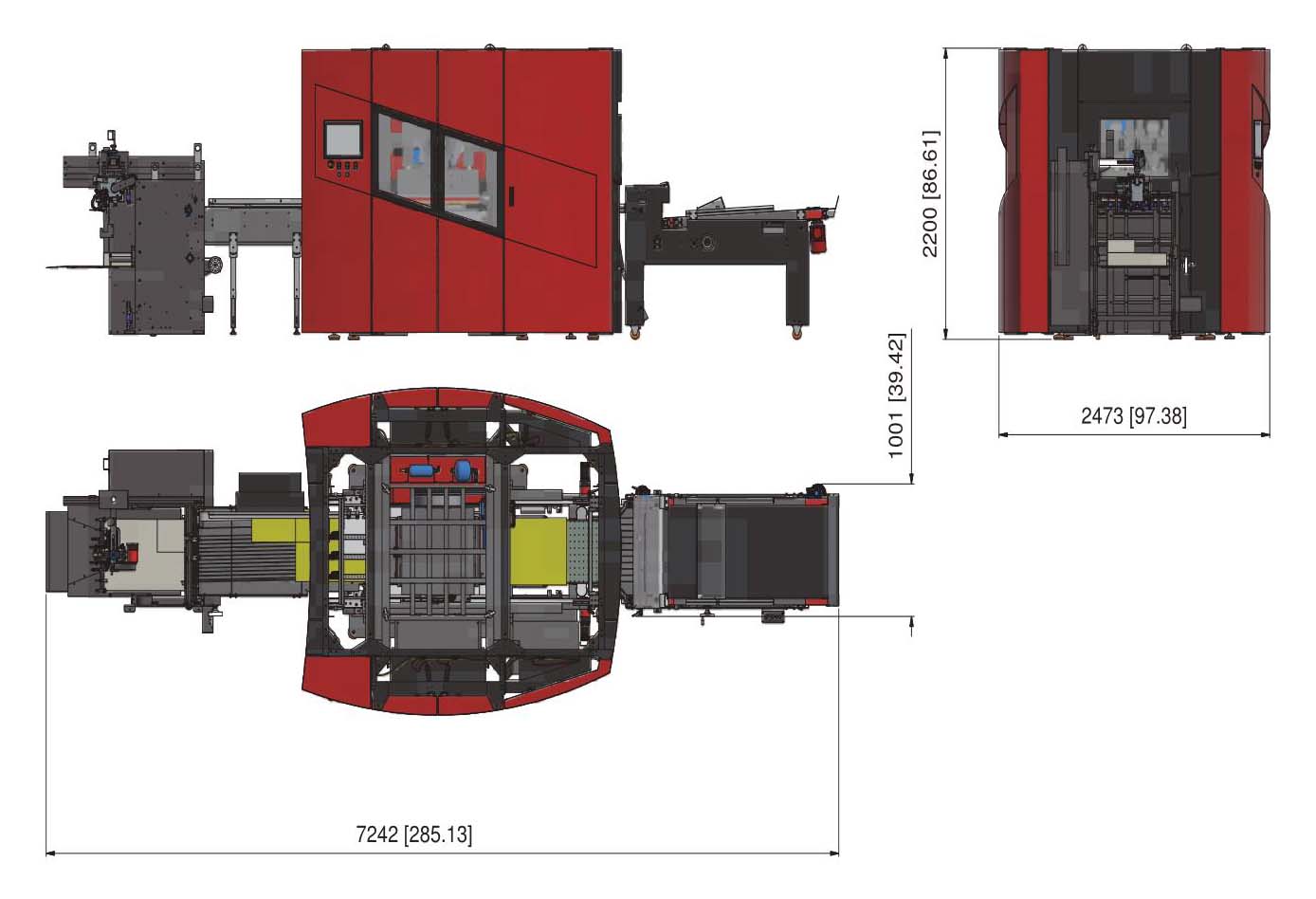

- Compact automatic die-cutter, robustly constructed

- NO STOP production

- Short set-up times and easy make-ready

OPERATION

The unit works horizontally, with sheet transport to the die cut station achieved by the means of the driving clamps. This innovative method ensures excellent quality and results, and adds more value to the finished job. DCH200 allows both the traditional way of die cutting a full sheet and our proposal of die cutting by MULTISHAPE on the same sheet. This way reduces setting time, cost of the die cutting tool and patching time. Thus the unit is particularly suitable for use by printers who will satisfy the die cutting market needs from small to medium runs.

DCH200IT

DCH200IT  DCH200ENG

DCH200ENG  DCH200ES

DCH200ES